Robots from Pozega conquer the world - Immold Plast expects turnover of EUR 10 m approximately

Monday, 10.08.2015.

Monday, 10.08.2015.

00:43

00:43

He brought to new company extensive experience in construction of tools for injection filling and automated systems for industry IML (In Mold Labeling) of packing. Jankovic has been in private sector since 1994 when he first became its co-owner and the head of Sevojno-based ATM,.

(Goran Jankovic)

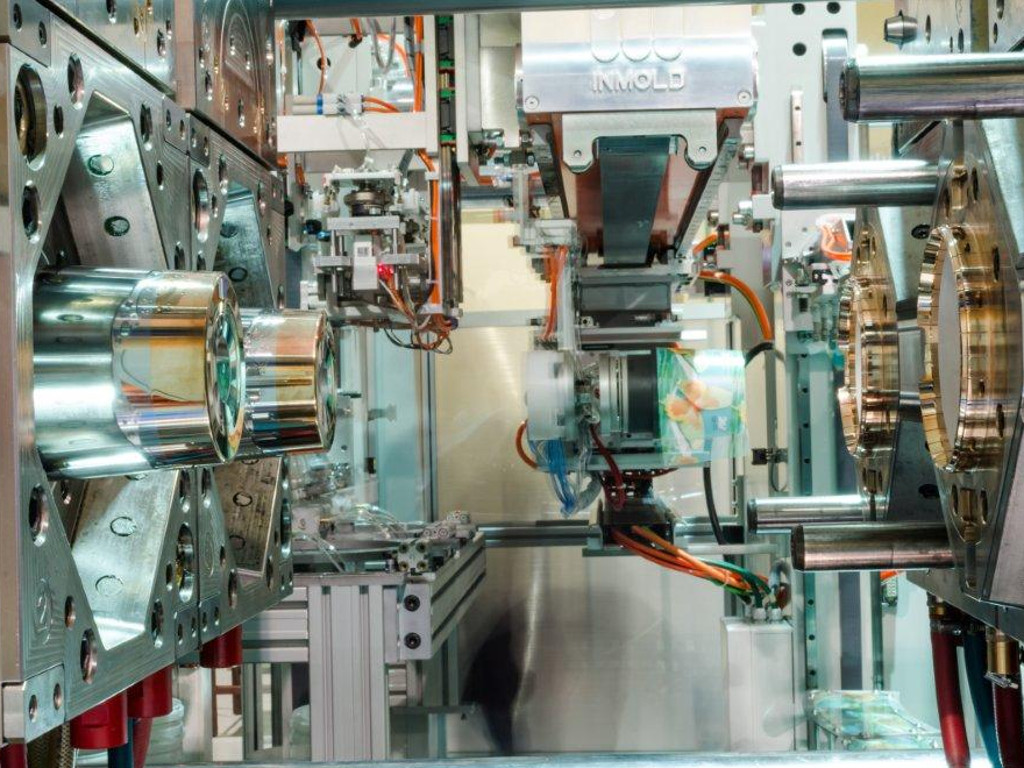

Basic company’s products are tools for production of plastic parts and robots for production of thin wall packaging whch, according to our collocutor, og top quality and in line with the most modern European competitors in this. Tools are long lasting, designed, produced and tsted in Pozega. They are made of highly quality materials on new CNC and other specialized machines. Inmold provides both support and service for delivered tools and specialized IML equipment. It has constantly been introducing latest technology and investing in staff training.

In the beginning, Jankovic worked alone and later a few members from wider family and closest neighbors joined him. Today, Inmold Plast has 155 employees.

He says production has developing trend every year and in metal and mechanical industry it is a remarkable result having in mind situation this activity is in Serbia. Entire production process from idea to production of finished tools which is delivered to a buyer is done in Pozega-based plant and in each its department, Inmold Plast uses equipment of renowned European companies.

Jankovic is satisfied with business results in 2015 and expects turnover of EUR

10 m EUR.

Inmold has knowledge, resources and technological capacities with which it provides a number of benefits for its partners such as putchase of equipment in the form of overall production systems and product which is cheaper compared to other world producers. Apart from that, quality of delivered equipment is competitive to the world and there is an option of staff training and maintenance. Thus, huge funds are saved since services of foreign companies in this sector are very expensive.

Goran Jankovic outlines his main challenge in current business has been how to

make in Serbia a company which will ne at the European level and he stresses

out as major problems lack of qualified

staff and low expert knowledge in this field.

Dual education in practice

(Short summer school)

Goran Jankovic is one of rare businessmen in Serbia who invests in prosperity of young people, both students and students of technical faculties. He, as someone who respects the youth and technique, merged these two in a unit and with its vision 4 years ago brought something to Pozega which has been now discussed in the public - dual education system which enables young people to train themselves at Inmold Plast.

Owner and head at Inmold Plasta has organized this summer Short summer practical training as a kind of education, both for scholarship students and students at mechanical faculties where they could acquire basic skills of handling universal and CNC machines.

This year, from the first generation of scholarship students, 4 students found their permanent job at Inmold Plast and replaced their student books with the work ones.

Inmold Group d.o.o. Požega

Inmold Group d.o.o. Požega

ATM SEVOJNO

ATM SEVOJNO

Fond za razvoj Republike Srbije Niš

Fond za razvoj Republike Srbije Niš

Tehnička škola Požega

Tehnička škola Požega

Izdanje Srbija

Izdanje Srbija Serbische Ausgabe

Serbische Ausgabe Izdanje BiH

Izdanje BiH Izdanje Crna Gora

Izdanje Crna Gora

News

News