Production of industrial equipment – Transformation of industrial plants

Source: eKapija

Thursday, 24.11.2022.

Thursday, 24.11.2022.

02:43

02:43

Thursday, 24.11.2022.

Thursday, 24.11.2022.

02:43

02:43

(Photo: IZIT)

Industrial manufacturers of such equipment have constant demands for robust, consistent, accurate and continuous parts, regardless of the complexity of the geometry. If they do not meet these conditions, there will be frequent breakdowns, as well as additional costs and a damaged reputation.

The challenges of industrial production do not stop here. In addition to all the aforementioned challenges, the equipment must be produced on time and cheaply.

With traditional production technologies, we count on high costs and a long time of preparation for production. This means that traditional technologies will often be an obstacle in creating a flexible production system. The production of industrial equipment must be reliable, consistent and efficient, with a short delivery time.

Pushing the boundaries in additive manufacturing

Fortunately, there is an alternative to conventional manufacturing – Stratasys` SAF industrial powder 3D printing technology. Using a single print head pass for printing and powder bonding, this device offers manufacturers a simple and robust way to produce controlled, precise and continuous products that would be conventionally injection molded. Also, this technology has reached the "gold standard" with its ability to produce tens of thousands of parts with consistent properties. This means that this technology can compete with traditional technologies such as injection molding and milling even in large series.

Finally, SAF technology offers manufacturers the flexibility that is of key importance today in a manufacturing sector that is constantly changing and evolving.

Production of industrial equipment: The right moment for the right machine

Stratasys brought SAF technology to market with the H350 3D printer, designed for the precision, continuity and process control necessary for manufacturing success. The production of industrial equipment with this printer is experiencing a real renaissance. Stratasys had similar requirements when manufacturing the H350 3D printer, so only reliable parts were installed to guarantee top performance.

Since every 3D printer must behave the same, it is of great importance that all parts meet high criteria reliably and continuously. If one of the parts were out of tolerance, the H350 would not function properly. This would negatively affect the device`s ability to continuously and accurately produce items.

In addition to quality, this technology provides short time for the production of parts.

With all these factors in mind, Stratasys decided to demonstrate confidence in its own platform and produced the final parts of the device on the H350 3D printer.

In total, about thirty parts for the H350 were produced using the test H350 printers. They are made of PA11 material and are installed directly in the device. This type of production has allowed Stratasys to go to market faster, produce despite reduced supply, save on transportation costs, and produce reliably.

Some of the parts produced and built into the newest Stratasys 3D printer (Photo: IZIT)

It`s all in the details

The powder suction has been slightly reworked throughout the development process. The part is located on the front of the powder unit and connects to the hose connected to the powder tank. It serves to deliver powder into the working volume of the device. In order to avoid dust being blown into the room, the diameter must be precise. The screw holes must be in the correct places to easily connect the housing and intake with screws. A groove was added to easily clamp the hose to the suction. The tolerances for this part are precise and must be continuous.

Powder suction for Stratasys H350 3D printer (Photo: IZIT)

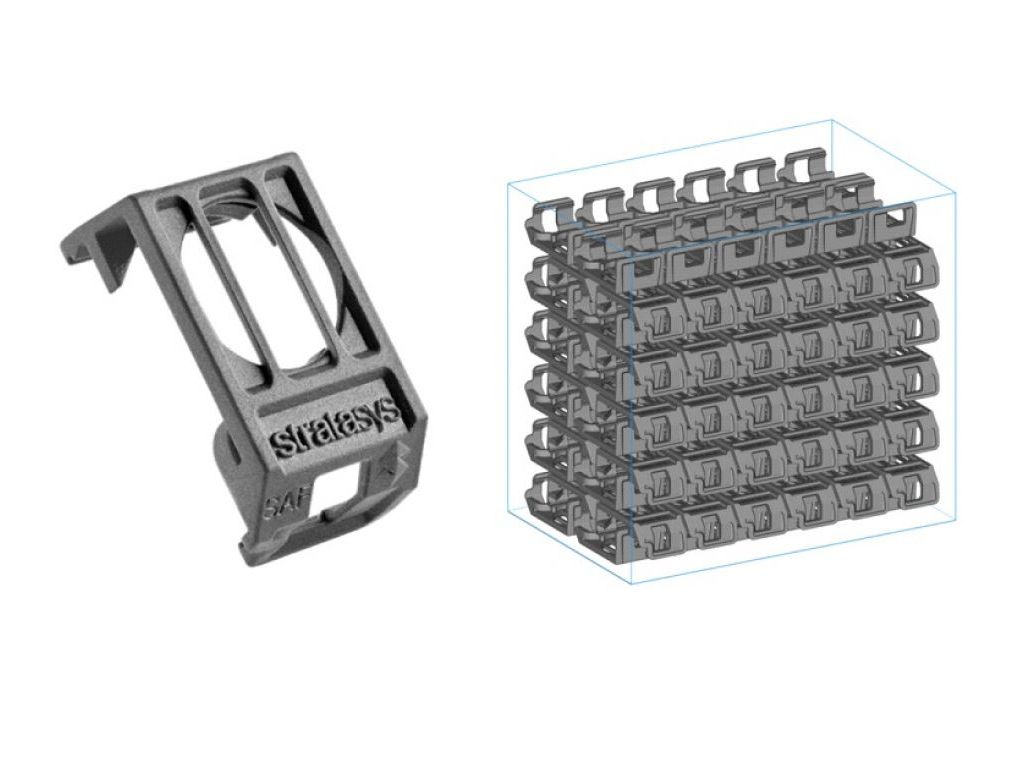

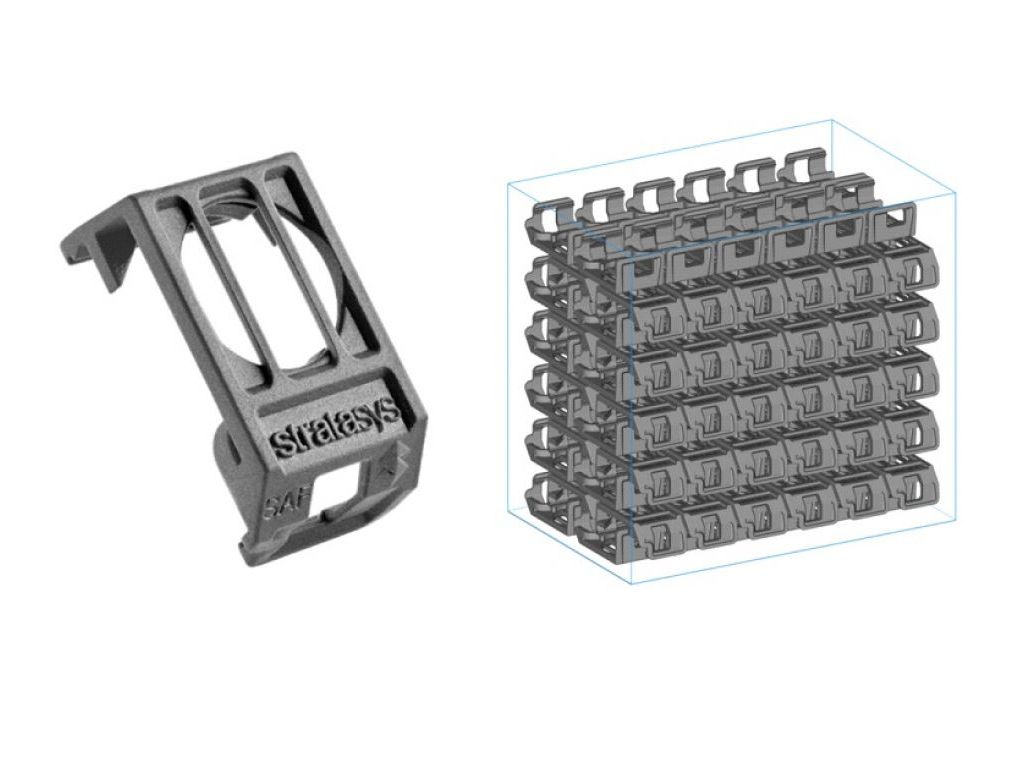

Complex geometry is key

The ink supply hose clip supplies liquid material to the print head. This part prevents the hose from getting tangled at the entrance to the print head. Although this part is standardized, in this case it was adapted to suit our needs and to support larger bending angles in a smaller space. All the details of this part were achieved on the H350 without fail.

Ink supply hose clip for Stratasys H350 3D printer (Photo: IZIT)

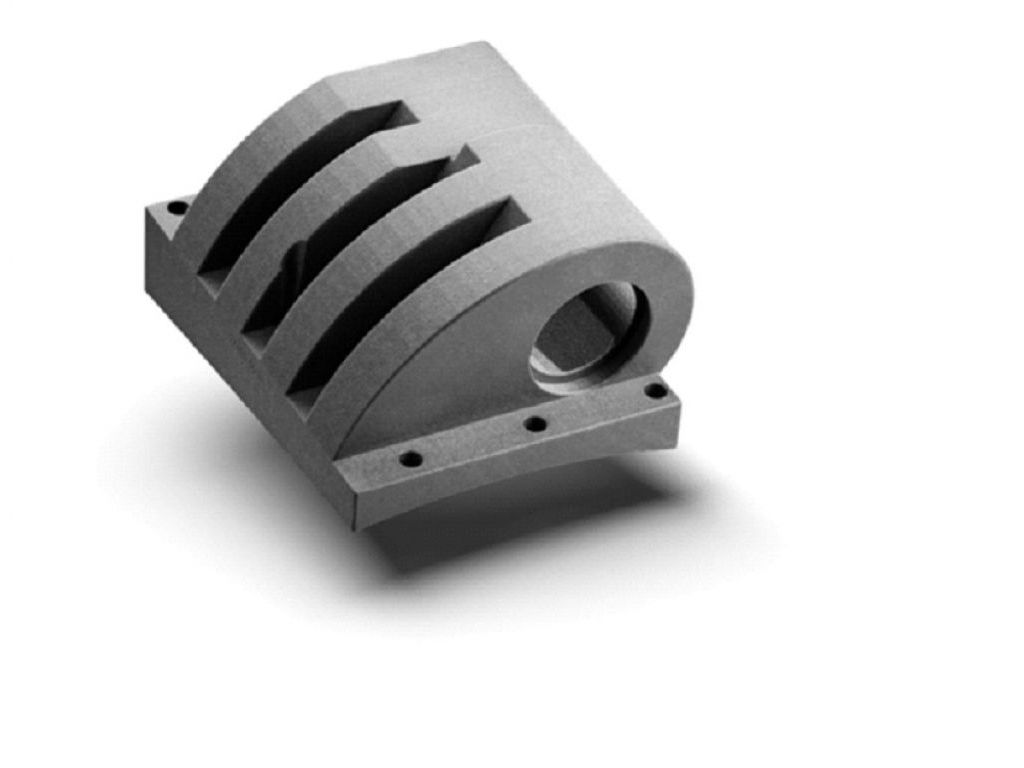

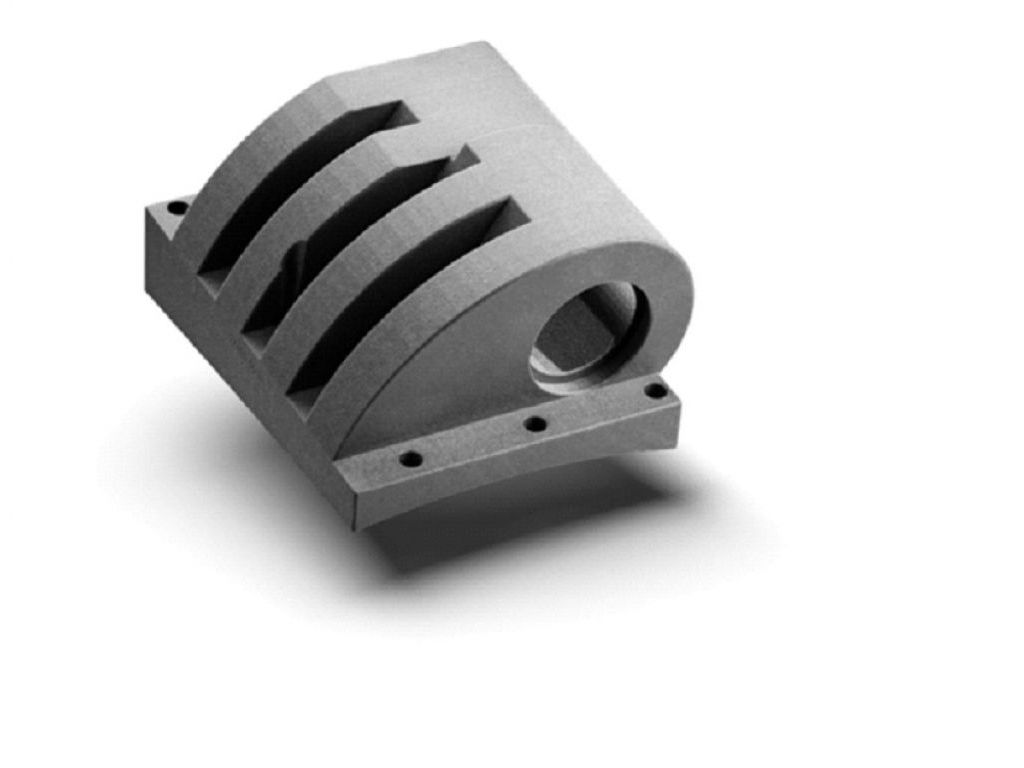

SAF technology overrides CNC

The powder hopper hinge consists of angled sides that abut the curved surfaces of the powder hopper. This object has no straight sides and is tilted in all three axes. With traditional technologies such as milling, these geometric characteristics are demanding to achieve. Also, this part must meet the tolerances of connecting the reservoir and the intake. This part is manufactured easily and precisely using SAF technology.

Powder hopper hinge for Stratasys H350 3D printer (Photo: IZIT)

Maintaining accurate dimensions and diameters

The box for the electronics fan filter has an internal opening that must fit perfectly with the cover. Dimensional stability is also crucial in order for the entire box to fit in its intended place inside the housing of the H350 3D printer. The part consists of long flat plates reinforced by ribbing on the surface. On 3D printers using powder, it is notoriously difficult to get accurate flat plates due to the tendency for the object to deform, but due to superior temperature control, all parts were produced within tolerances.

Box for the electronics fan filter for Stratasys H350 3D printer (Photo: IZIT)

Small parts in tight spaces

The clip for the ink supply consists of two concave plates that hold the copper tubes for the ink supply to the print head. The flexibility in production allowed the creation of a small object so that it could be installed in a limited space. This part is easy to produce continuously and accurately.

The clip for the ink supply consists of two concave plates that hold the copper tubes for the ink supply to the print head. The flexibility in production allowed the creation of a small object so that it could be installed in a limited space. This part is easy to produce continuously and accurately.

Clip for the ink supply for Stratasys H350 3D printer (Photo: IZIT)

Emphasis on toughness

The elastic clip for the wiring guide serves to prevent unwanted interaction between wires and moving parts. That clip has to fulfill many functions at once, from avoiding motherboards and connectors to ensuring sufficient tube length when moving the 3D print head. The conductors it protects are fragile and their safety is of great importance, even at elevated temperatures. The toughness of PA11 powder allows this functionality. H350 produces parts with exceptional mechanical properties, including superior ductility.

Elastic clip for the wiring guide for Stratasys H350 3D printer (Photo: IZIT)

Parts perfected for production

The wire guides for the 3D lamp have a unique geometry and are located on the 3D print head. In order for the wires to maintain their function, they must be protected from sharp edges. As the part is in an atmosphere of elevated temperature, PA11 was the ideal choice for the functional part.

The wire guides for the 3D lamp have a unique geometry and are located on the 3D print head. In order for the wires to maintain their function, they must be protected from sharp edges. As the part is in an atmosphere of elevated temperature, PA11 was the ideal choice for the functional part.

Wire guide for the 3D lamp for Stratasys H350 3D printer (Photo: IZIT)

Redefining the supply chain

The motor controller PCB board was originally ordered from an outside supplier. Due to supply changes during COVID-19, the original tile is no longer produced. This led the team to develop a new solution and use a new board that requires active cooling. In order to add that functionality, we had to add a place to mount the fan. The engineering team relied on the H350 to produce the new mount. Ribs were added and tolerances were defined to easily attach the tile to the support. The holder takes up minimal space and does not use any tools or screws. Without the possibility of producing parts as needed, this problem would not be solved. Also, this part was particularly economical with a price of under 4 euros per piece.

Motor controller PCB board for Stratasys H350 3D printer (Photo: IZIT)

Consistency, resilience and complete control of the production process

By producing these parts on the Stratasys H350 3D printer, the products were completed in just a few hours, which saved weeks of waiting for parts to be delivered. With regard to some parts, supply was no longer a limiting factor in printer production. With the ability to produce parts on demand, you can also produce parts accurately, precisely and continuously. Our unshakable confidence in the H350 proved to be justified in every situation.

Companies:

Izit d.o.o.

Izit d.o.o.

Tags:

IZIT doo from Croatia

Stratasys

SAF technology

SAF industrial technology

3D print

3D printer

3D printing

powder 3D print

special edition newsletter Digital Transformation Roadmap to eFuture

Comments

Your comment

Most Important News

Full information is available only to commercial users-subscribers and it is necessary to log in.

Follow the news, tenders, grants, legal regulations and reports on our portal.

Registracija na eKapiji vam omogućava pristup potpunim informacijama i dnevnom biltenu

Naš dnevni ekonomski bilten će stizati na vašu mejl adresu krajem svakog radnog dana. Bilteni su personalizovani prema interesovanjima svakog korisnika zasebno,

uz konsultacije sa našim ekspertima.

Izdanje Srbija

Izdanje Srbija Serbische Ausgabe

Serbische Ausgabe Izdanje BiH

Izdanje BiH Izdanje Crna Gora

Izdanje Crna Gora

News

News