Leaders of cement industry decarbonization - Lafarge Serbia on the path to carbon neutrality

Tuesday, 09.04.2024.

Tuesday, 09.04.2024.

23:41

23:41

This new industrial policy based on the circular economy seems to bring the most challenges to the construction sector, which contributes as much as 38% to the total world carbon dioxide emissions.

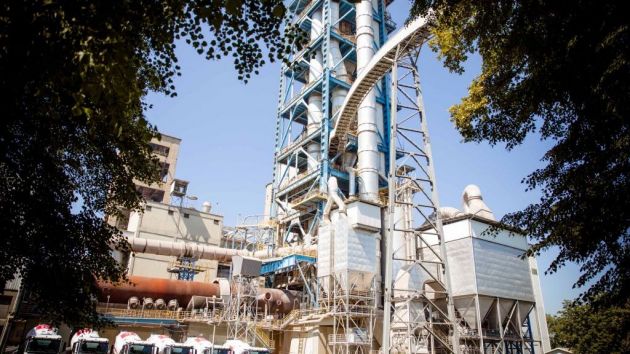

However, many will be surprised that, thanks to innovative solutions offered by, among others, the company Lafarge Serbia based in Beočin, significant progress has already been made in this field in our country.

- The Lafarge Serbia company, as part of the Holcim Group, has committed to zero carbon dioxide emissions by 2050 and to a direct contribution to environmental protection and slowing down climate change. As a leader in the construction materials market, they are determined to be an example to other participants in the construction sector - they emphasize in the company, but they note that successfully decarbonizing the industry will not be possible without close cooperation of the industrial sector with the regulatory bodies of the Republic of Serbia.To begin with, since the decarbonization of all business activities is the company`s basic strategic stronghold, the company reveals to us that the moment has arrived for the oldest and far-famed Beočin cement type CEM I to go down in history after 184 years of production. As they say, instead of CEM I, Primate will take over a revolutionary portfolio of new green cements that emit up to 30% less CO2.

New cements for a new culture of construction - BEOMAX extreme & BEOUNO

BEOMAX extreme - with up to 15% less emitted CO2, is intended for industrial producers, such as producers of prefabricated concrete elements or finishing materials in construction. BEOMAX extreme has successfully replaced the flagship of the Lafarge product range – pure Portland cement.

- With the unique cement BEOMAX extreme, we managed to make a revolutionary step in the construction industry and after 184 years of production, we relegate to history the unique cement of the CEM I mark, which emits the most carbon dioxide into the atmosphere during production - Lafarge Serbia is proud.

BEOUNO - with up to 30% less emitted CO2, intended for the production of transport concrete from general requirements to very specific ones where it is able to meet conditions that other types of cement cannot - such as low heat of hydration or chemical resistance. In other words, BEOUNO represents "one cement for all purposes"

.

Launched concrete with 50% less CO2

But that`s not all. Lafarge Serbia also launched concrete with 50% less carbon dioxide. It is the ECOPact Prime brand.

ECOPact Prime concretes from Lafarge Serbia directly contribute to the decarbonization of construction, thanks to innovative recipes, which enable the reduction of carbon dioxide emissions by up to 50% per cubic meter of concrete produced.

The possibility of reducing CO2 emissions in cement factories in Serbia will depend primarily on the availability of alternative materialsAbout 75% of the total waste in Serbia is construction waste. According to statistics, three to four million tons of waste are produced annually in our country, and in Belgrade alone, between 300 and 700 thousand tons

While today the life cycle of this waste ends completely with its disposal in landfills throughout Serbia, the cement industry offers a circular solution.

By establishing a system that diverts construction and demolition waste to cement factories instead of landfills, multiple contributions would be achieved. On the one hand, the amount of waste disposed of in landfills and their negative impact on the environment would be reduced, and the exploitation of natural raw materials used in cement production would also be reduced.

- Given that the process of decarbonization in construction waste is already completely completed, replacing the basic natural raw materials for the production of clinker - limestone and marl with waste from construction and demolition, gives us the opportunity to significantly reduce carbon dioxide emissions that originate from the production process - they point out in the Lafarge Serbia company.

As they say, by recycling construction waste and returning it to cement, they can now at the same time directly reduce the exploitation of natural raw materials, but also drastically reduce CO2 emissions per produced ton of cement.

Experts from the development center of the Holcim Group, of which we are a part, work every day on the development of innovative construction products, proving that it is possible to develop cements and concretes that contain up to 100% recycled construction materials without impairing the product`s performance. We are building more, with less extracted natural raw materials! - they say.

By-products of other industries such as slag and fly ash can hardly find a use value.

- However, for us, they represent a valuable raw material for the production of cement, without compromise when it comes to the quality of the cement. In this way, we give waste materials a completely new life - they emphasize from the Lafarge company.

Alternative fuels instead of fossil

It is already known that alternative fuels emit up to 55% less CO2 compared to traditional fuels, and this is the reason why Lafarge Serbia is increasingly turning to alternative fuels and making constant efforts to, despite the challenges, maximize the share of alternative fuels in its production .

In particular, the availability of alternative fuels to replace fossil fuels and the possibility of using construction and demolition waste (CDW) as a substitute for natural raw materials, which carry about 50% of emissions from the production process, will be of crucial importance for reducing CO2 emissions in the cement production process.

_________________________

As a reminder, with the introduction of the Carbon Border Adjustment Mechanism - CBAM (Carbon Border Adjustment Mechanism), which was adopted by the European Parliament at the end of last year, producers from Serbia, from six industries - cement, iron and steel, electricity, aluminum, fertilizers and hydrogen, from January 1, 2026, are obliged to pay the CBAM tax on the carbon dioxide they emit when exporting their products to the EU in the production process. - This directly points to the fact that the decarbonization strategy is indispensable, to begin with in the business of energy-intensive branches of industry - they note in the company Lafarge Serbia. ______________________ |

They also emphasize the importance of the regulatory bodies of the Republic of Serbia, i.e. that they have a key role to play - through the adjustment of regulations and the adoption of new legal frameworks - to enable the implementation of the CO2 emission reduction strategy, in order to create more favorable conditions for the green transition of the industry operating in Serbia.

- In particular, the Ministry of Environmental Protection, the Ministry of Mining and Energy, as well as the Ministry of Construction, Transport and Infrastructure are our key partners in the introduction of green construction and the direct reduction of carbon dioxide emissions in this industry - conclude the leaders of Lafarge Serbia and in the end they say:

- The availability of energy and raw materials and the predictability of regulations are a necessary prerequisite for preserving the competitiveness of the cement industry in Serbia and the contribution it makes to economic growth, innovation and employment. In front of us is the opportunity to, in synergy with state institutions, start the path towards decarbonization of industry in Serbia.

United, we make this world a better place to live!

Click here to see the entire Special Edition Newsletter

"Green (r)evolution - The future has begun"

LAFARGE BFC SRBIJA DOO BEOČIN

LAFARGE BFC SRBIJA DOO BEOČIN

Izdanje Srbija

Izdanje Srbija Serbische Ausgabe

Serbische Ausgabe Izdanje BiH

Izdanje BiH Izdanje Crna Gora

Izdanje Crna Gora

News

News